PRODUCTS SERIES

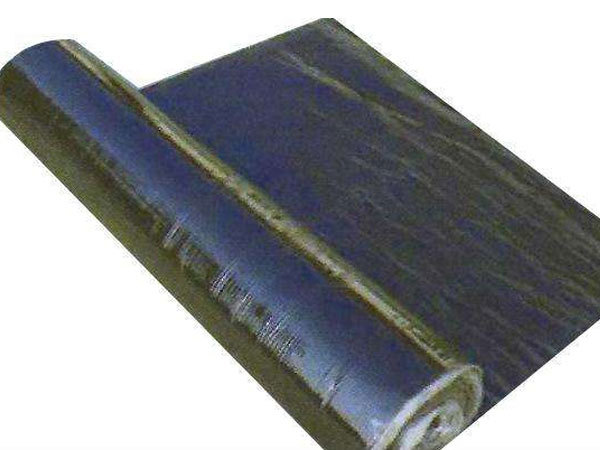

Elastomer Modified Asphalt Waterproofing Membrane

Elastomer (SBS) modified asphalt waterproofing membrane implementation of national standards GB18242-2008, is made of styrene-butadiene-styrene (SBS) rubber modified asphalt as a coating, with glass fiber felt, polyester felt, glass fiber reinforced polyester felt for the tire base, both sides covered with isolation material made of a waterproof material with excellent performance, with heat, cold, corrosion resistance, anti-aging, good thermoplasticity, high tensile strength, high elongation, strong tear resistance. Good thermoplasticity, high tensile strength, high elongation, strong resistance to tearing and other advantages.

Keywords:

Category:

Waterproof board

Email:1071173371@qq.com

Elastomer Modified Asphalt Waterproofing Membrane

Detail

Product introduction:

Elastomer (SBS) modified asphalt waterproofing membrane implementation of national standards GB18242-2008, is made of styrene-butadiene-styrene (SBS) rubber modified asphalt as a coating, with glass fiber felt, polyester felt, glass fiber reinforced polyester felt for the tire base, both sides covered with isolation material made of a waterproof material with excellent performance, with heat, cold, corrosion resistance, anti-aging, good thermoplasticity, high tensile strength, high elongation, strong tear resistance. Good thermoplasticity, high tensile strength, high elongation, strong resistance to tearing and other advantages.

Product characteristics.

1, the product has a unique high-temperature resistance, but also has good low-temperature flexibility, both at the same time.

2、Good water resistance, strong abrasion and corrosion resistance, wide range of application.

3、Good elasticity, large elongation, strong ability to adapt to grass-roots deformation.

4、Both hot melt method and cold bonding method can be used for construction.

Product use:

applicable to industrial and civil buildings such as roofs, basements, walls, bathrooms, pools, drains, subways, caves, highways, bridges and airport runways and other waterproof protection projects, and for metal containers, pipeline anti-corrosion protection, is a widely used, excellent performance of waterproof materials, both single-layer use, can also be compound; both hot-melt construction, can also be cold bonding, glass fiber reinforced polyester felt membrane can be used for Mechanically fixed single-layer waterproofing, but need to pass the wind load test, glass fiber felt coil is suitable for multi-layer waterproofing of the bottom layer of waterproofing, exposed use of the upper surface isolation material for opaque mineral granules waterproofing membrane, waterproofing underground projects using surface isolation material for fine sand waterproofing membrane.

Classification and specifications:

according to the tire base is divided into polyester felt (PY), glass fiber felt (G), glass fiber reinforced polyester felt (PYG).

By the upper surface isolation material is divided into polyethylene film (PE), fine sand (S), mineral granules (M). The lower surface isolation material is fine sand (S), polyethylene film (PE).

According to the material performance is divided into Ⅰ-20℃ type and Ⅱ-25℃ type.

The nominal width of the coil is 1000mm.

Polyester felt coil nominal thickness of 3mm, 4mm, 5mm.

The nominal thickness of glass fiber felt coil is 3mm, 4mm.

Nominal thickness of glass fiber reinforced polyester felt rolls is 5mm.

The nominal area of each roll is 7.5 square, 10 square and 15 square.

Implementation standard: GB18242-2008

Table 1 Unit area quality, area and thickness

Table 2 Material properties

Previous

Polyvinyl Chloride (PVC) Waterproofing Membrane

Online consultation