PRODUCTS SERIES

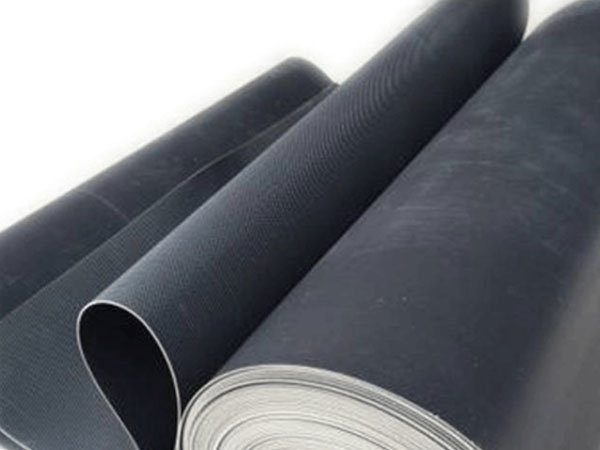

Plastic Modified Asphalt Waterproofing Membrane

Plastic modified asphalt waterproofing roll-roofing refers to the polyester tire, glass fiber felt, glass fiber reinforced polyester felt as the tire base, with random polypropylene (APP) or polyolefin polymers (APAO, APO, etc.) as petroleum asphalt modifier, both sides covered with isolation material made of waterproofing roll-roofing.

Keywords:

Category:

Waterproof board

Email:1071173371@qq.com

Plastic Modified Asphalt Waterproofing Membrane

Detail

Product Description.

Plastic modified asphalt waterproofing roll-roofing refers to the polyester tire, glass fiber felt, glass fiber reinforced polyester felt as the tire base, with random polypropylene (APP) or polyolefin polymers (APAO, APO, etc.) as petroleum asphalt modifier, both sides covered with isolation material made of waterproofing roll-roofing.

Product Type.

According to the tire base is divided into polyester felt (PY), glass fiber felt (G), glass fiber reinforced polyester felt (PYG)

According to the upper surface isolation material is divided into polyethylene film (PE), fine sand (S), mineral granules (M). The lower surface isolation material is fine sand (S), polyethylene film (PE).

According to the material performance is divided into type I and type II

Specifications.

Commonly used width 1000mm

Thickness of polyester felt rolls: 3mm 4mm 5mm

Glass fiber felt roll thickness: 3mm 4mm

Glass fiber reinforced polyester felt roll thickness: 5mm

Marking: products by name, model, tire base, upper surface materials, lower surface materials, thickness, area and standard number order mark

Example: 10m2 area, 3mm thick, the upper surface of mineral granules, the lower surface of polyethylene film, polyester felt Ⅰ plastic modified asphalt waterproofing roll-roofing marked: APP Ⅰ PY M PE 3 10 GB 18243-2008

Product features.

1, the product has a unique high temperature resistance, but also has a good low temperature flexibility, both.

2、Good water resistance, strong abrasion and corrosion resistance, wide range of application.

3、Good elasticity, large elongation, strong ability to adapt to the deformation of the grass-roots level.

4、It can be constructed by both hot melt method and cold bonding method.

Scope of application.

1, generally used in industrial and civil buildings waterproof.

2, applicable to a variety of underground engineering waterfront waterproofing.

3, bridges, roads, parking lots, subways, tunnels and other municipal engineering waterproofing.

Executive standard: JCT1075-2008

Table 1 Mass, area and thickness per unit area

Table 2 Material properties

Previous

Root Puncture Resistant Waterproofing Membrane For Planted Roofs

Online consultation