PRODUCTS SERIES

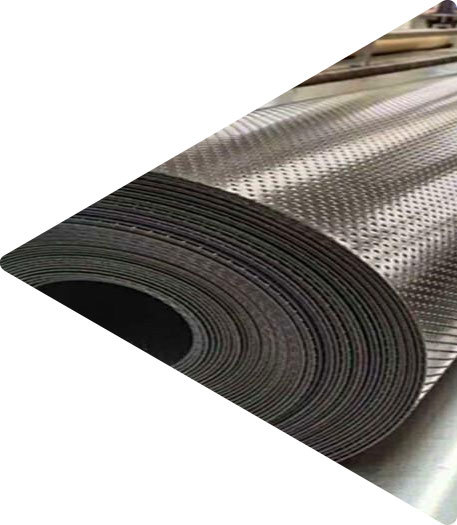

Rough Geomembrane

Rough geomembranes are divided into single and double rough surfaces, which are generally used in landfills and are laid on slopes to increase the friction so that the membrane does not slip down on the slope. There are three types of rough geomembranes, i.e., starting rough mask, spray rough mask and column point rough mask.

Keywords:

Category:

Geomembrane

Email:1071173371@qq.com

Rough Geomembrane

Detail

Product Introduction

Rough geomembranes are divided into single and double rough surfaces, which are generally used in landfills and are laid on slopes to increase the friction so that the membrane does not slip down on the slope. There are three types of rough geomembranes, i.e., starting rough mask, spray rough mask and column point rough mask.

First of all, it is the use of blow molding process nitrogen browning, using a three-layer co-extrusion process, that is, there are three barrels into the material, there are two barrels responsible for the two sides of a barrel responsible for the middle of the film. Roughening mask in the production process due to the destruction of the surface of the geomembrane, resulting in a relatively low fracture strength.

The process is to produce a glossy geomembrane first, and then spray the plastic filaments on the glossy surface through special equipment to increase the friction of the membrane, which is strong because it does not destroy the surface of the membrane.

Column point geomembranes are produced by a special steel rod with a concave point, and the membrane is produced using the extrusion and cooling of the steel rod. This results in the production of column point geomembranes, which are also relatively strong. The thickness of the above three types of rough geomembranes is between 1.0mm - 2.0mm, which has both good impermeability and increases the friction between the geomembrane and the slope surface, making it easy to construct.

Specifications and performance parameters

High density polyethylene geomembrane with rough surface for environmental protection(GH-2T1 ,CH-2T2 type)

| No. | Item | Indicators | ||||||

| Thickness mm | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

| 1 | Density g/cm³ | ≥0.940 | ||||||

| 2 | Height of roughness mm | ≥0.25 | ||||||

| 3 | Tensile yield strength (longitudinal and transverse) N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile breaking strength (longitudinal and transverse) N/mm | ≥8 | ≥10 | ≥13 | ≥16 | ≥21 | ≥26 | ≥32 |

| 5 | Field service elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal, transverse) % | ≥100 | ||||||

| 7 | Right-angle tearing load (longitudinal and transverse) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

| 8 | Puncture resistance N | ≥200 | ≥270 | ≥335 | ≥400 | ≥535 | ≥670 | ≥800 |

| 9 | Tensile load stress cracking (notched constant load tension method) h | ≥300 | ||||||

| No. | Item | Indicators | ||||||

| Thickness mm | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

| 10 | Carbon black content % | 2.0~3.0 | ||||||

| 11 | Carbon Black Dispersibility | No more than 1 out of 10 data level 3, level 4 and 5 are not allowed | ||||||

| 12 | Oxidation induction time (OIT) min | Atmospheric pressure oxidation induction time ≥ 100 | ||||||

| High pressure oxidation induction time ≥ 400 | ||||||||

| 13 | Thermal aging at 85 ℃ (OIT retention at atmospheric pressure after 90 d) % | ≥55 | ||||||

| 14 | Resistin external line (OIT retention after 1600 h of UV irradiation) % | ≥50 | ||||||

| Note: The technical performance index requirements for thickness specifications not listed in the table are implemented in accordance with the interpolation method. | ||||||||

| Serial number 2 indicators in 10 tests, the results of 8 times should be greater than 0.18 mm, the minimum value should be greater than 0.13 mm. Serial number 13, 15 two indicators of atmospheric pressure OIT (retention rate) and high pressure OIT (retention rate) can choose either one of the test. |

||||||||

Previous

Next

Previous

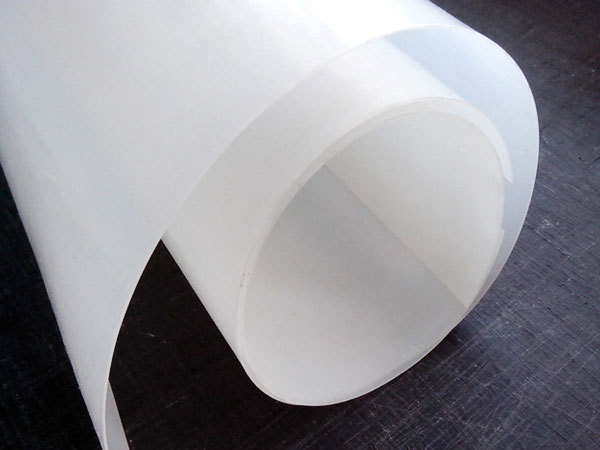

Glossy Geomembrane

Next

Online consultation