17

2018

-

10

Interpretation of Series Standards for Geosynthetics (3): Technical Standard for Geosynthetics for Railway Engineering (Q/CR 549

Author:

I. Introduction

With the rapid development of economy, the types, varieties and quantities of geosynthetics products in China are gradually increasing, and their application scope and application fields are becoming more and more extensive. In order to promote the standardization and standardization of geosynthetics products, unify the relevant technical requirements of products, and ensure the quality of products and projects, the geosynthetics products and application technical standards or specifications have been compiled or revised by relevant industries in China recently. In order to facilitate colleagues to timely understand the relevant standards (specifications) information and grasp the latest developments, the Secretariat of China Geosynthetic Materials Engineering Association has been collecting and sorting out the relevant standards and specifications for geosynthetics.

This issue introduces the standard of China Railway Corporation, Geosynthetics for Railway Engineering Part 3 Geosynthetics (Q/CR 549.3-2016), which was promulgated and implemented on January 8, 2017.

Necessity of compilation

Geomembrane has been widely used in the field of railway engineering. For example, it is used to reinforce new railway subgrade bed in railway subgrade engineering. The existing railway subgrade bed is treated with diseases such as mud boiling and ballast pouring. Expansive soil, loess and other special rock and soil areas are prevented from seepage under surface water. Saline soil and frozen soil areas are separated from underground capillary water. In tunnel waterproof and drainage engineering, after tunnel lining. Geomembrane is laid for waterproofing, and composite geomembrane is laid under the base plate for skid-proof in slab ballastless track structure.

Although geomembrane has been widely used in many fields and different types of applications, and its technical requirements are different, there has been no corresponding product standards in the railway industry. The design, construction and inspection parameters of railway engineering construction projects are formulated mainly according to national or other industry standards in design and construction, which results in inconsistencies in the standards of geomembrane products used in the railway industry, and the inspection methods and methods. Means are not uniform, there are many human control factors, and the quality of on-site products is difficult to control.

In order to ensure engineering quality, absorb new technical achievements, standardize the application of Geomembrane in railway engineering design and construction, embody the characteristics of railway engineering and unify relevant technical requirements, China Railway Corporation has established the product standard of "Geosynthetic Material Part 3 Geosynthetic Membrane for Railway Engineering".

Main Contents of Standards

(1) The classification method, naming format, product specifications and application scope of geomembrane products were formulated.

(2) Technical requirements for Geomembrane and composite geomembrane products for railway engineering have been formulated, and clear requirements have been put forward in terms of raw materials, appearance quality and technical performance.

(3) The test methods of sampling and sample preparation, appearance and size of geomembrane products are put forward, and the tensile fracture strength, yield strength and elongation, puncture resistance, carbon black content, carbon black dispersion, density, right angle tear load, oxidation induction time, low temperature impact embrittlement property, dimensional stability and tensile fracture strength of composite geomembrane are formulated. Degree and elongation, CBR breaking strength, hydrostatic pressure, mass per unit area, tearing strength, Dynamic perforation (falling cone), friction coefficient, in-plane water flow, creep performance, oxidation resistance, acid and alkali resistance, breaking strength, joint/joint breaking strength, ultraviolet resistance, permeability coefficient, wear resistance, peeling strength, constant load elongation and constant elongation load, etc. The principle, equipment, sample and test procedure of the main test are specified in detail in the form of appendix.

(4) The inspection rules for Geomembrane products are formulated, including inspection classification, factory inspection, type inspection, batch and sampling, and determination rules.

(5) Specific requirements for marking, packaging, transportation and storage of geomembrane products are specified.

4. Brief introduction of some standards

Below is a brief introduction to some of the contents of the standard. For more details, please read the product standard.

(1) The classification of geomembrane products in railway engineering is stipulated.

(1) Geomembranes are classified as high density polyethylene (HDPE) geomembrane according to raw materials.

(2) Composite geomembrane can be divided into non-woven composite geomembrane and woven composite geomembrane according to the type of base material products.

(3) Composite geomembrane can be divided into waterproof and partition composite geomembrane, transverse drainage composite geomembrane and reinforced composite geomembrane according to its function.

(4) Composite geomembrane can be divided into one cloth-one film and two cloth-one film according to product structure.

(2) The naming standard of geomembrane products in railway engineering has been determined.

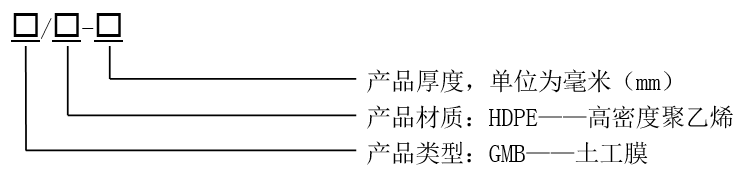

The product naming format of geomembrane is as follows:

For example, GMB/HDPE-0.3 indicates that the geomembrane material is high density polyethylene with a film thickness of 0.3 mm.

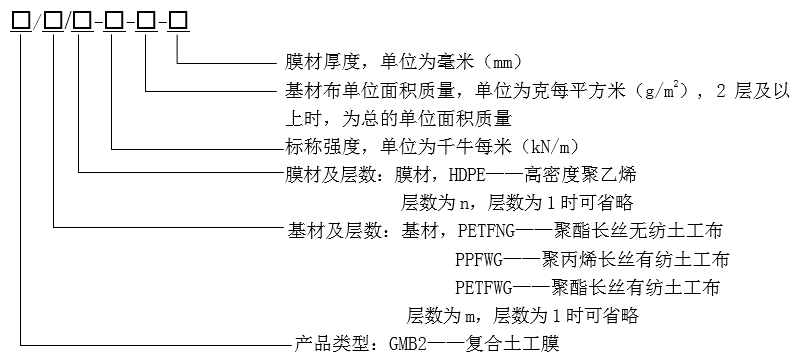

The naming format of composite geomembrane products is as follows:

For example, GMB2/PETFNG2/HDPE-16-700-0.35 indicates: composite geomembrane, base material is two layers of polyester filament nonwoven geotextile, membrane material is one layer of high density polyethylene geotextile membrane, two layers and one film, nominal strength is 16 kN/m, total area mass is 700 g/m2, film thickness is 0.35 m M.

(3) Define the scope of application of geomembrane products in Railway Engineering

Geomembrane and composite geomembrane are widely used in railway engineering, roadbed engineering is mainly used for foundation reinforcement, treatment of foundation bed diseases, prevention of surface water seepage or separation of underground capillary water in special rock and soil areas, waterproofing and drainage after lining in tunnel engineering, waterproofing and drainage under ballastless track structure and skid prevention.

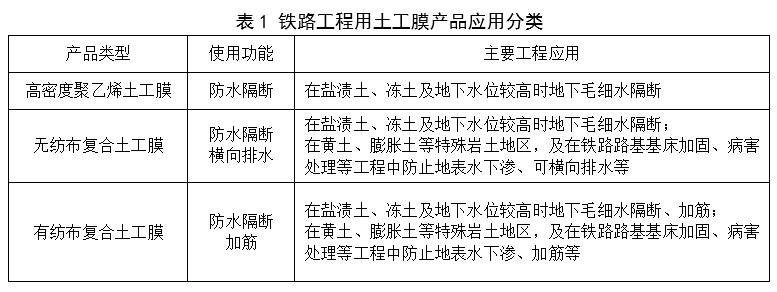

As the Drainage Plate of Railway Tunnel has been compiled in railway tunnel engineering, the performance requirements and engineering application effect of composite geomembrane under the base plate of track engineering need to be tested, so the compilation of geomembrane standard only aims at geomembrane products applied in subgrade engineering. In railway subgrade engineering, its main functions are waterproof partition, transverse drainage and reinforcement. The main application scope of geomembrane products is shown in the following table:

(4) Provision of technical specifications for Geomembrane products in Railway Engineering

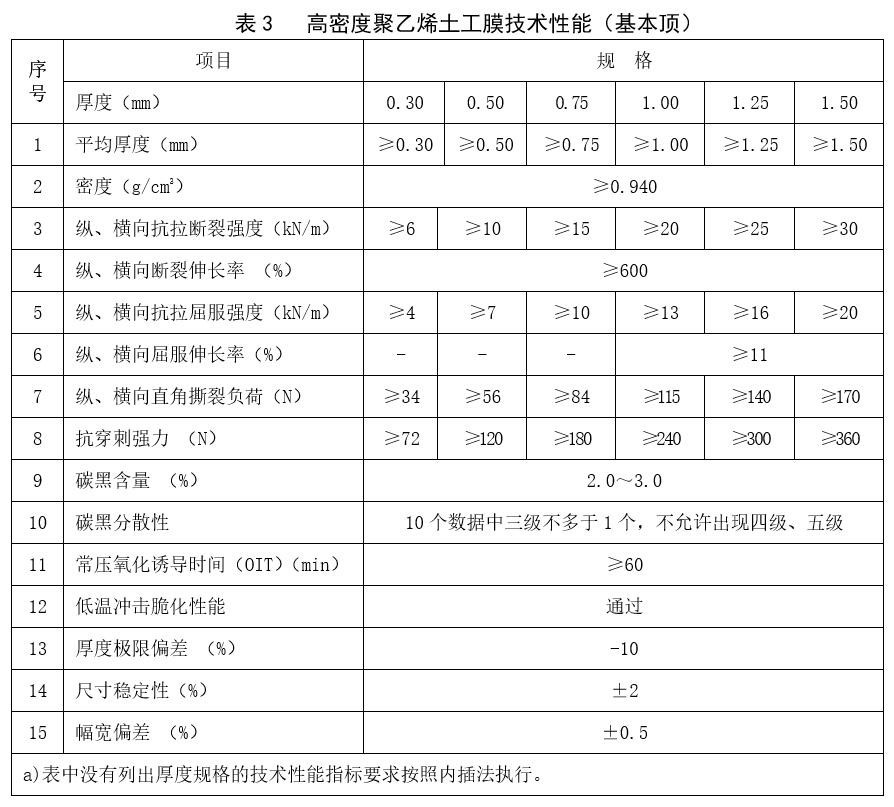

This standard divides technical indicators into basic items and selection items. The basic items are the index requirements that the product must meet, and the selection items are the index requirements that must be met according to the design or actual needs. Taking high density polyethylene geomembrane as an example, the specific requirements of its technical performance are as follows:

undefined