17

2018

-

10

Interpretation of Geosynthetics Series Standards (2): Geosynthetics Technical Standard Geogrid Chamber for Railway Engineering (

Author:

I. Introduction

With the rapid development of economy, the types, varieties and quantities of geosynthetics products in China are gradually increasing, and their application scope and application fields are becoming more and more extensive. In order to promote the standardization and standardization of geosynthetics products, unify the relevant technical requirements of products, and ensure the quality of products and projects, the geosynthetics products and application technical standards or specifications have been compiled or revised by relevant industries in China recently. In order to facilitate colleagues to timely understand the relevant standards (specifications) information and grasp the latest developments, the Secretariat of China Geosynthetic Materials Engineering Association has been collecting and sorting out the relevant standards and specifications for geosynthetics.

This issue introduces the standard of China Railway Corporation, Part 1 Geotechnical Cell of Geosynthetics for Railway Engineering (Q/CR 549.1-2016), which was promulgated and implemented on January 8, 2017.

Necessity of compilation

Geotechnical cell is a three-dimensional structure consisting of honeycomb or grid connected by polymer sheets. It is often used in the fields of foundation reinforcement, foundation treatment, slope green protection, embankment reinforcement and reinforced earth retaining wall. Geotechnical cell is widely used in highway subgrade engineering. The product standard "JT/T 516-2004 Geotechnical Cell of Highway Engineering Geotechnical Synthetic Material" has been issued; the national standard "GB/T 50290-98 Geotechnical Synthetic Material Application Technical Specification" edited by the water industry has been incorporated into the geotechnical cell; at the same time, the national product standard "GB/T 19274-2003 Geotechnical Cell of Geotechnical Synthetic Material" from light engineering. From the industry point of view, the classification, performance requirements and test methods of geocell products are stipulated. The application of geocell in railway subgrade engineering is gradually popularized, but in the process of popularization, it mainly refers to national standards and relevant industry standards. Because the railway subgrade has its own characteristics, if the current national standards and related industry standards are adopted, not only the design and construction will remain unchanged, but also the quality of the project will be difficult to control. In order to standardize the quality and application scope of geocell for railway subgrade in China, promote the standardization, standardization and serialization of geocell products, unify the relevant technical requirements of products, and ensure the quality of projects, China Railway Corporation has compiled and promulgated and implemented the product standard of "Part 1 geocell for railway engineering geosynthetics".

Main Contents of Standards

(1) Technical requirements such as terminology and definition of geocell are formulated.

(2) The classification method, naming format, product specifications and application scope of geocell products are formulated.

(3) The appearance requirements of geocell products, raw material standards, physical, mechanical, durability and other technical performance indicators were formulated.

(4) The inspection rules for geocell products are formulated, including inspection classification, factory inspection, type inspection, batch and sampling, and determination rules.

(5) The label, packing, transportation and storage of geocell products are stipulated.

(6) The testing methods for the appearance, size, tensile yield strength, right-angle tear resistance, environmental stress cracking, oxidation induction time, carbon black content, carbon black dispersion, ultraviolet resistance, peeling strength at cell junction, tensile strength at cell junction, suspension load-bearing time and inter-group tensile strength of geocell products were developed, and each of them was tested in the form of appendix. The principle of the test, the state adjustment of the sample, the standard environment of the test, the test equipment, the preparation of the sample, the test procedure and the calculation are stipulated.

Below is a brief introduction to some of the contents of the standard. For more details, please read the product standard.

(1) The naming standards of geocell products in railway engineering are defined.

In order to unify the naming of geocell products in railway engineering, the naming format of geocell products determined in this standard is: connection type + geocell. For example: welded geocell, plastic bolt connected geocell, etc.

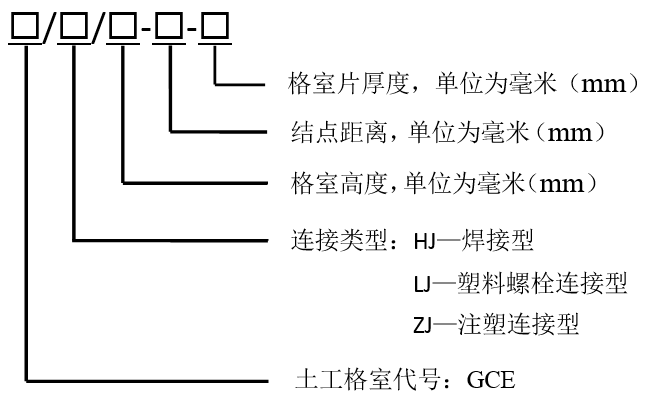

On the symbol of geocell product, the format is shown in the following figure.

For example, GCE in GCE/HJ/75-200-0.8 indicates that the connection type is welded geocell with a height of 75 mm, a distance of 200 mm and a thickness of 0.8 mm. GCE/LJ/100-250-1.1 indicates that the connection type is plastic bolt connection type, the height is 100 mm, the node distance is 250 mm, and the thickness of the geocell is 1.1 mm.

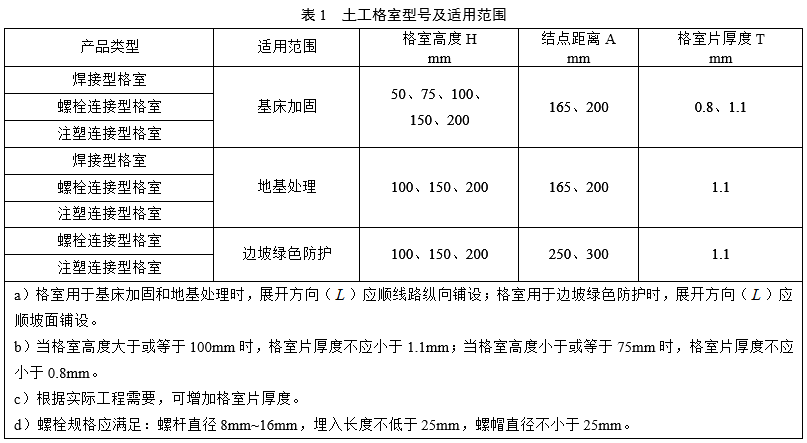

(2) The types of geocell products in railway engineering are specified.

Considering the existing geocell products and their application in Railway Engineering construction, the geocell in this standard only includes welded geocell, plastic bolted geocell and injection-moulded geocell. With the large-scale construction of railway projects in China and the gradual application of geocell, other geocell products with relatively mature application will be added to this standard in due course.

(3) Define the scope of application of geocell products in Railway Engineering

(1) Welded cell, bolted cell and injection-moulded cell are mainly used in the reinforcement of foundation.

(2) Welded cell, bolted cell and injection-moulded cell are mainly used in foundation treatment.

(3) In the green protection of slope, bolt-connected cell and injection-plastic-connected cell are mainly used.

(4) Provision of technical indicators for geocell products in Railway Engineering

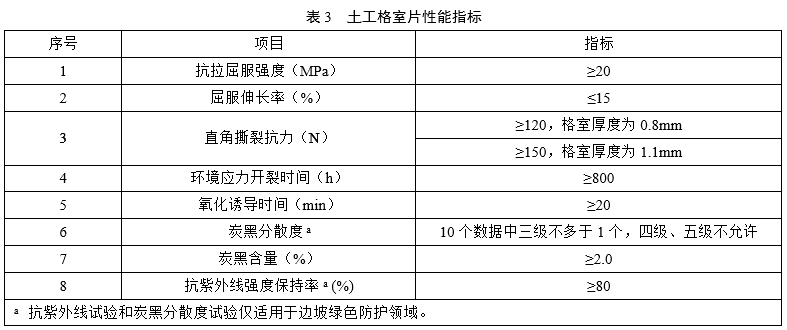

The physical, mechanical and durability indexes of geocell products of various types are specified in this standard.

Physical indicators include the width and length of a single group of geocell and the distance between the joints of the geocell sheets and the adjacent joints.

Mechanics indexes include tensile yield strength, yield elongation, right-angle tearing resistance, peeling strength and tensile strength of cell joints.

Durability includes: environmental stress cracking time, oxidation induction time, carbon black dispersion, carbon black content, ultraviolet resistance strength retention rate, suspension load-bearing time, ultraviolet resistance strength retention rate, etc.

undefined