17

2018

-

10

Interpretation of Geosynthetics Series Standards (1): Technical Standard of Geosynthetics for Railway Engineering Geosynthetics

Author:

I. Introduction

With the rapid development of economy, the types, varieties and quantities of geosynthetics products in China are gradually increasing, and their application scope and application fields are becoming more and more extensive. In order to promote the standardization and standardization of geosynthetics products, unify the relevant technical requirements of products, and ensure the quality of products and projects, the geosynthetics products and application technical standards or specifications have been compiled or revised by relevant industries in China recently. In order to facilitate colleagues to timely understand the relevant standards (specifications) information and grasp the latest developments, the Secretariat of China Geosynthetic Materials Engineering Association has been collecting and sorting out the relevant standards and specifications for geosynthetics, please look forward to it.

This issue introduces the standard of China Railway Corporation, Geosynthetic Material for Railway Engineering Part 2 Geogrid (Q/CR 549.2-2016), which was promulgated and implemented on January 8, 2017.

Necessity of compilation

With the rapid development of railway construction in China, considering the safety and importance of railway operation, strict requirements are put forward for the stability and deformation of railway roadbed, which should be designed and constructed as a structure. Based on the good reinforcement effect of geogrid, it has been widely used in subgrade engineering, which has played a positive role in improving the quality and durability of railway subgrade engineering and meeting the needs of Railway Engineering construction. At present, there are only two kinds of national standards: Geosynthetic Plastic Geogrid (GB/T 17689-2008) and Glass Fiber Geogrid (GB/T 21825-2008). The former is mainly formulated for the integral stretching plastic geogrid, lacking the technical indicators and parameters to meet the special requirements of railway engineering. The latter is mainly used for highway asphalt pavement reinforcement, can not be used for railway engineering. Although the Ministry of Transportation industry standard "Geosynthetic Geogrids for Transportation Engineering" (JT/T480-2002) contains almost all geogrids on the market at present, its technical indicators are not systematic and somewhat obsolete. Geogrid is used more and more in railway subgrade engineering, and the high standard of railway subgrade engineering puts forward strict requirements for Geogrid materials. However, the current national standard and the technical standard of geogrid defined by the Ministry of Transport and Communications industry standard can not meet the needs of Railway Engineering construction. In order to standardize the product quality and application scope of geogrids for railway subgrade in China, promote the standardization, standardization and serialization of geogrids for railway engineering, unify the relevant technical requirements of products and ensure the engineering quality, China Railway Corporation has compiled and promulgated the product standard of Geosynthetics Part 2 Geosynthetics for Railway Engineering.

Main Contents of Standards

(1) Technical requirements such as terminology and definition of geogrids have been formulated.

(2) The classification method, naming format, product specifications and application scope of geogrid products are formulated.

(3) The appearance requirements, raw material standards, physical, mechanical, durability and other technical performance indicators of geogrid products have been formulated.

(4) The inspection rules for Geogrid products are formulated, including inspection classification, factory inspection, type inspection, batch and sampling, and determination rules.

(5) The marks, packaging, transportation and storage of geogrid products are stipulated.

(6) The testing methods for the appearance, unit area quality, inner hole size and width, tensile strength and elongation, connection strength, ultimate peeling force of weld joints, carbon black content, carbon black distribution, creep reduction coefficient and ultraviolet resistance retention rate of geogrid products are developed. The principle of each test, the state adjustment of the sample and the test are described in appendix. Standard environment, test equipment, sample preparation, test procedure and calculation are stipulated.

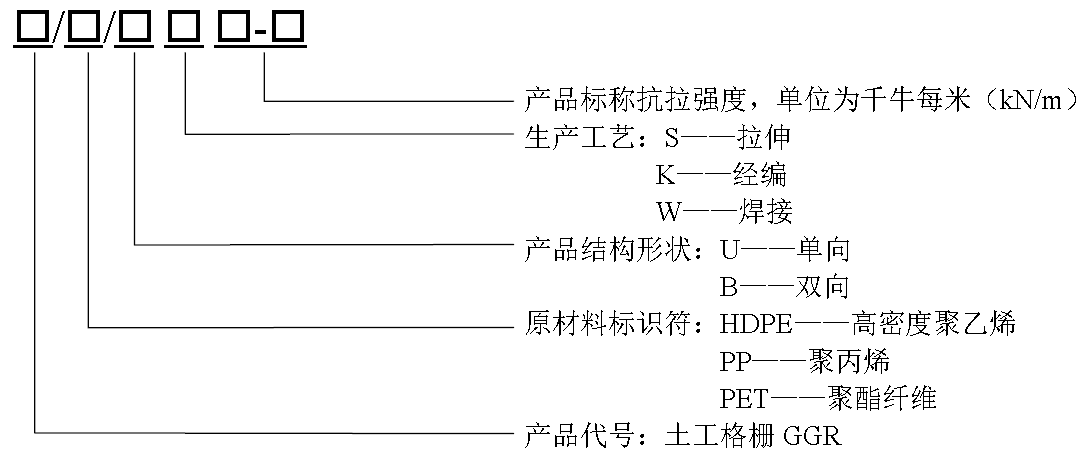

4. Define the naming standard of geogrid products in Railway Engineering

In order to unify the naming of geogrid products in railway engineering, the naming format of geogrid determined in this standard is: product structure + production process + raw materials + geogrid. For example: unidirectional tension plastic geogrid, bidirectional warp knitted polyester geogrid and so on.

The format of the geogrid product symbol is shown in the figure.

For example, GGR/HDPE/US80 indicates that the raw material is high density polyethylene (HDPE), and the nominal tensile strength is 80 kN/m unidirectional tensile plastic geogrid. GGR/PET/BW80-80 indicates that the raw material is polyester fiber (PET), and the longitudinal and transverse nominal tensile strength is 80 kN/m bidirectional welded polyester geogrid.

5. Types of Geogrid Products for Railway Engineering are specified

Considering the technical characteristics and special requirements of railway engineering construction in China, the Geogrids in this standard only include several types of geogrids, such as unidirectional tension plastic geogrids, biaxial tension plastic geogrids, bidirectional warp knitted polyester geogrids and bidirectional welded polyester geogrids.

With the large-scale construction of railway projects in China and the gradual application of geogrids, other geogrids with relatively mature applications will be added to this standard in due course.

6. Define the scope of application of geogrid products in Railway Engineering

(1) Geogrids used in reinforced earth retaining walls or steep slope of railway roadbed to improve structural stability through tension of reinforcement materials and interaction between reinforcement and soil are mainly made of unidirectional tension plastic geogrid (HDPE).

(2) Geogrids used for layered filling and compaction of railway embankments to prevent slope sliding are mainly biaxial tension plastic geogrid or biaxial warp knitted polyester geogrid.

(3) Geogrids used in railway engineering foundation treatment to coordinate stress and deformation are mainly single (double) tension plastic geogrid (PP), bidirectional warp knitted polyester geogrid or bidirectional welded polyester geogrid.

7. Provision of technical specifications for Geogrid products in Railway Engineering

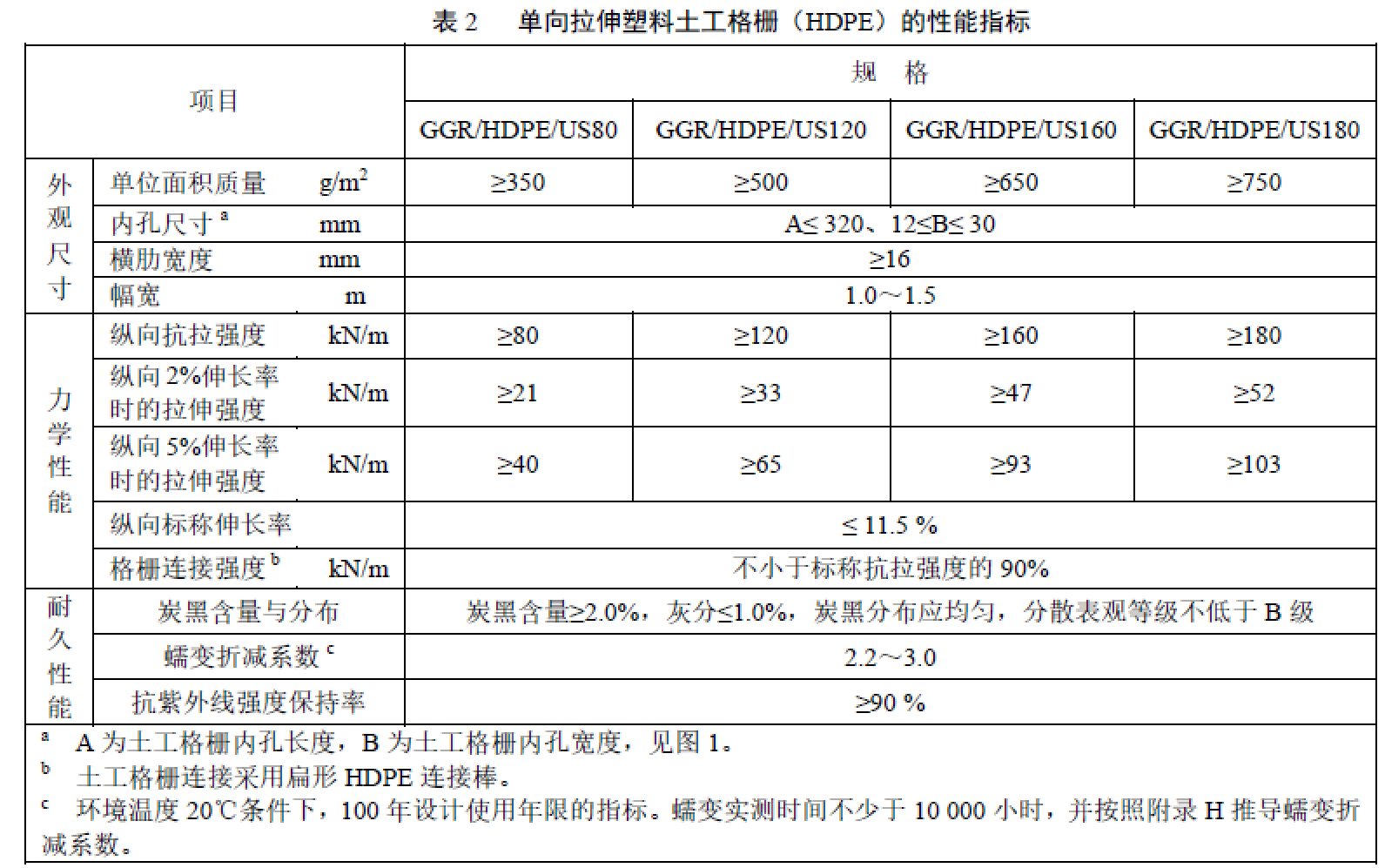

The physical, mechanical and durability indexes of various types of geogrid products are specified in this standard.

Physical indicators include unit area mass, inner hole size, width and transverse rib width (unidirectional tension plastic geogrid), etc.

Mechanics indexes include tensile strength, tensile strength at 2% and 5% elongation, nominal elongation and connection strength (unidirectional tensile plastic geogrid).

Durability includes ultraviolet resistance, carbon black content and distribution (tensile plastic geogrid), creep reduction factor (unidirectional tensile plastic geogrid), etc.

8. Types of Geogrid Products for Railway Retaining Structures

According to the survey of the reinforced earth retaining wall which has been built and opened to traffic in the railway industry in recent 15 years, almost all reinforced earth retaining walls use unidirectional tensile plastic geogrid (HDPE), and the reinforced earth retaining wall maintains good working performance. Therefore, this standard stipulates that unidirectional tension plastic geogrid (HDPE) is mainly used in geogrids suitable for retaining structures.

In the future, according to the corresponding research results and relevant engineering experience, other types of geogrid products with mature application and good engineering characteristics will be added into the reinforced materials for retaining structures in this standard.

undefined