PRODUCTS SERIES

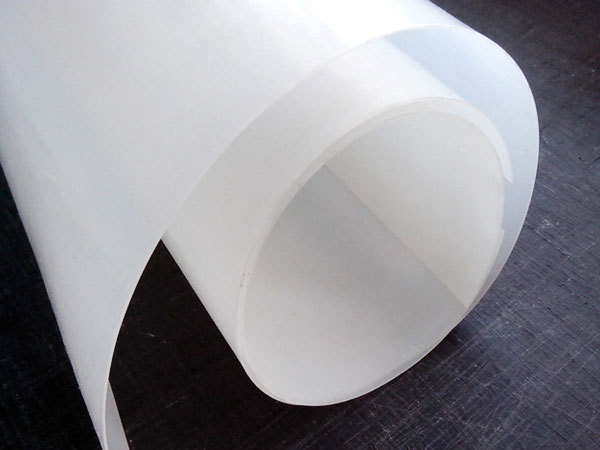

Back Patch Waterstop

Rubber waterstop and waterstop rubber are made of natural rubber and various synthetic rubber as the main raw materials, mixed with various additives and fillers, plasticized, blended and pressed into shape, with more varieties and specifications, including bridge type, mountain type, P type, U type, Z type, B type, T type, H type, E type, Q type, etc.

Keywords:

Category:

waterstop

Email:1071173371@qq.com

Back Patch Waterstop

Detail

Waterstop implementation standard: GB18173.2-2014

Product introduction:

Rubber waterstop and waterstop rubber are made of natural rubber and various synthetic rubber as the main raw materials, mixed with various additives and fillers, plasticized, blended and pressed into shape, with more varieties and specifications, including bridge type, mountain type, P type, U type, Z type, B type, T type, H type, E type, Q type, etc. Natural rubber or various synthetic rubber as the main raw material, mixed with a variety of additives and fillers, plasticized, mixed, calendering and vulcanization processes. According to the use of the situation can also be classified as buried rubber water stop and backing rubber water stop. The water stop material has good elasticity, wear resistance, aging resistance and tear resistance, strong ability to adapt to deformation, good waterproof performance, the temperature range is -45℃-+60℃. When the temperature exceeds 70 ℃, as well as rubber water stops by strong oxidation or by oil and other organic solvent erosion, are not allowed to use rubber water stops. Generally, it is often used in the construction of basement exterior wall and back pouring zone.

Scope of application:

Rubber water stop is mainly used for concrete cast-in-place in the construction joints and deformation joints and concrete structure into one of the foundation projects, such as underground facilities, tunnels and culverts, water transfer channels, dams, liquid storage structures, etc.

Use method:

The rubber waterstop must take reliable fixing measures when tying reinforcement and supporting the mold. Prevent displacement when pouring concrete to ensure the correct position of the waterstop in the concrete.

Only perforated holes in the allowable parts of the waterstop, for fixing the waterstop. Shall not damage the effective waterproof part of the waterstop.

Commonly used fixing methods are:

The use of additional reinforcement fixed; special clamps fixed; with lead wire and template fixed. Regardless of what kind of fixing method, for the waterstop fixing method should be in accordance with the design requirements of the construction specifications and the need to ensure accurate positioning of the waterstop, do not damage the effective waterproof parts of the waterstop, convenient concrete pouring

Performance and parameters

Previous

Next

Previous

none

Next

Online consultation