08

2019

-

01

Sponge City Construction and Geosynthetic Materials (6): Geosynthetic Materials in Permeable Ponds, Seepage Wells and Seepage Pi

Author:

In the process of construction of sponge city, we should coordinate the systematization of natural precipitation, surface water and groundwater, coordinate water supply and drainage, and consider its complexity and long-term. In order to meet the above requirements, geosynthetics are mainly used in seepage pond, seepage well and Seepage Canal sponge urban development facilities, such as geomembrane and geotextile, as seepage control, filtration and drainage materials.

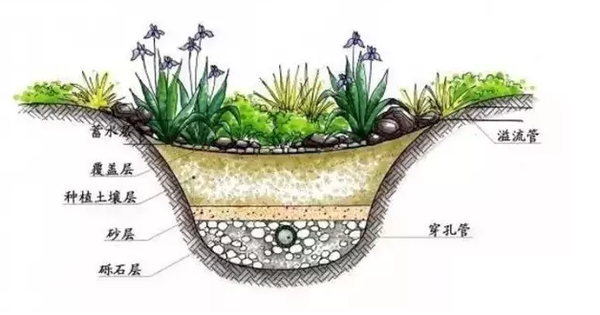

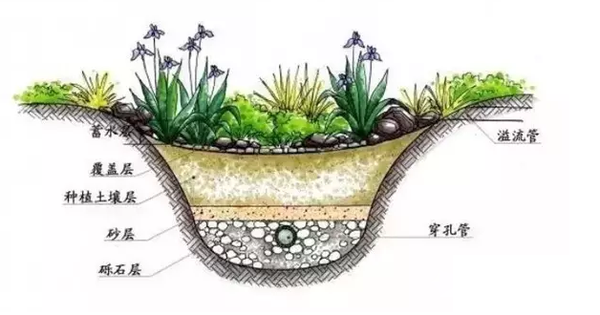

Seepage pond

In low-lying areas with certain spatial conditions, such as catchment area larger than 1 hectare and low-lying terrain, infiltration ponds should be used. The Infiltration Pond should be equipped with pre-treatment facilities such as pre-pond and overflow facilities. Energy dissipation stone and gravel should be set up at the intake of the front pond to slow down the flow scouring. When the water flow is fast, the energy dissipation stones should be larger and buried deeply and exposed shallowly. The overflow between the front pond and the main pond should be protected by gravel and pebble to prevent water from scouring and damaging the overflow weir. The particle size of gravel and pebble should be 4.75 mm~9.50 mm, the mud content should not be more than 1.5%, and the mud content should not be more than 0.5%. The slope of the seepage pond slope is generally less than 1:3, the water level from bottom to overflow is generally not less than 0.6m, and the drainage time of the seepage pond should not be more than 24h. The bottom structure of seepage pond should adopt good permeable materials. It can use 200 mm ~ 300 mm planting soil, permeable cloth and 300 mm ~ 500 mm filter medium layer. The performances of pervious geotextiles shall conform to the specifications. Herbs should be planted in infiltration ponds, and drought-tolerant and hard-working varieties should be selected. Pipes such as emptying pipes and emptying pipes should conform to GB/T 20221 of the current national standard "Unpressurized Buried Hard Polyvinyl Chloride (PVC-U) Pipes for Sewerage and Drainage" and GB/T 10002.1 of the current national standard "PVC-U Pipes for Water Supply" under pressurized conditions. When the seepage pond is used in areas where runoff pollution is serious, the seepage surface at the bottom of the facility is less than 1 m from seasonal maximum groundwater level or the rock layer is less than 1 m from the building level and the foundation is less than 3 m from the building level, seepage control measures such as laying geomembrane should be taken to prevent secondary disasters.

Seepage well

Seepage wells should be set up in the surrounding green areas of buildings, roads and parking lots in buildings and districts under better soil permeability conditions. The water source of seepage well should be pretreated by grass planting ditch, vegetation buffer zone and other facilities, and the inner and bottom elevation of outlet pipe should be higher than the top elevation of inlet pipe, but not higher than the bottom elevation of outlet pipe of adjacent upstream wells. PE (polyethylene) material should be used in water catchment and permeability inspection wells. The wellbore and bottom hole are perforated with permeability function. The hole opening rate should be more than 15%. The nominal diameter of the wellhead should be 600 mm to 800 mm, and the well depth should be less than or equal to 1 m to 1.4 M. The seepage wells should be matched with seepage pipes, the pits of catchment seepage wells and radiation seepage wells should be filled with coarse sand, and the surrounding wells should be filled with gravel. The mud content of gravel should be less than 1%, and the particle size range should be 16 mm to 64 mm. The gravel layer of seepage well should be wrapped with permeable geotextile, and the performance index of permeable geotextile should conform to the specification.

A seepage pipe or canal.

Seepage pipes or seepage canals can be used in areas with small transfer flow and good soil permeability in buildings, districts and public green spaces. Seepage pipes or seepage canals should not be used in areas with high groundwater level, serious runoff pollution and structural collapse. Pretreatment facilities such as grass planting ditch and sedimentation tank should be set up for seepage pipe or seepage channel. Gravel or other porous materials should be filled around the seepage pipe or seepage canal, and the gravel layer should be surrounded by permeable geotextile. Permeable pipes should be used in conjunction with seepage wells. Perforated plastic pipes, sand-free concrete pipes and other pervious materials should be used in seepage ditches, and the following requirements should be met: 1. Pipes should conform to the current national standard "Unpressurized buried sewage and drainage rigid polyvinyl chloride (PVC-U) pipes" GB/T 20221, and under pressure conditions should conform to the current national standard "Water Supply rigid polyvinyl chloride (PVC-U) pipes". The regulations of GB/T 10002.1 for vinyl (PVC-U) pipes; 2. The diameter of permeable pipes should not be less than 150 mm, the opening rate of plastic pipes should not be less than 15%, the porosity of sand-free concrete pipes should not be less than 20%; 3. The gradient of pipeline laying between inspection wells should be 1%~2%. The finished PE permeable drainage ditch should be used in the seepage ditch. The opening rate should not be less than 15%, and the depth and width should be 300 mm to 500 mm. Gravel or other porous materials with a void ratio of 35%~45% should be filled around the seepage pipe or canal, and a permeable geotextile with a thickness of not less than 1.2 m m and a mass of not less than 200 g/m 2 per unit area should be used to isolate the backfill with a compactness of about 92%. The performances of pervious geotextiles shall conform to the standards and specifications.

Teandersheng Building Material Co., Ltd. welcomes your call to consult geosynthetics geogrid, geotextile, geomembrane, tunnel waterproof board, EVA waterproof board, plastic drainage board and other geotechnical materials.

undefined